Steel Plastic Geogrid

2024-9-23

back

back

Release dateпјҡ2024-9-23

SourceпјҡOriginal

AuthorпјҡShandong Sunshine New Material Technology Co., Ltd

Pageviewsпјҡ82446

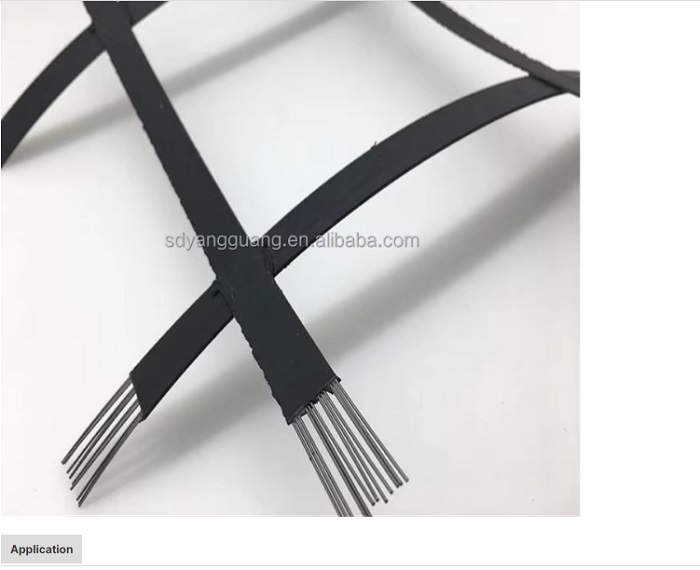

High tensile strength road construction PE steel wire biaxial Steel Plastic geogrid

The steel plastic welded geogrid uses high tensile steel wire (or other fiber)specially handled and polyethylene(P.E)with other assistants. Then squeeze it out and make it become composite high-strength anti-pull belt and the surface has rough embossing then it is reinforcement earthwork belt.Warp knitting vertically and horizontally using this single belt and welding the joint using a special welding techology to molding is reinforcement geogrid

1) High intensity and small distortion

2) Slow creep

3)Anti-corrosive, long-term service life, steel plastic geogrid material with steel plastic material as its protector, and with various accessory ingredients to make the product have the abilities if anti-aging and anti-oxidation resisting permant project more than 100 years, and the performance is superior, the size stability is good.

4) The construction is convenient, the cycle is short, the cost is low; it is easy to lay down, join, locate, avoids overlapping cross over, but reduces the project cycle effectively, saves the building cost of projects by 10%--50%.

1) Well pull: Longitudinal and crosswise tensile strength per linear meter can reach 20 to 150 KN.

2) Small deformation: the yield elongation of steel plastic integral geogrid is not bigger than 3%.

3) Nodal point is high.

4) Lifespan is long. It has the properties of anti - oxidation and anti - aging. It can be possible to meet each kind of permanent works and its lifespan can be 100 years above.

5) It can reduced the project cycle effectively and saved 10% to 50% of the building cost of projects.

6) The construction is convenient. It is easy to lay, join, locate and flat.

Consultation